Upholstery Foam Product Spotlight Video

Outdoor Foam

If you want to use foam outdoors, you can’t go wrong with Eva-Dri or EZ-Dri outdoor foam. They’re both medium density, but they are designed to let water flow through them rather than absorbing it like a sponge. The open cell construction also lets humidity and moisture evaporate quickly. EZ-Dri foam also has a built in fungicidal additive that inhibits fungus and mildew. This will help prevent stains and odor.

Rebond Foam

For a firmer foam that’s very durable, try rebond foam. It’s a dense, open cell foam that provides solid support and holds its shape well. It’s commonly used for commercial upholstery, motorcycle and snowmobile seats, bar stools, massage tables, and exercise mats.

Sew Foam

Sew foam has a cloth backing which makes it easy to work with for upholstery projects. This foam is commonly used to make custom automobile, motorcycle, and boat seats, as well as for headliner backings and car door panels. It can be sewn to the back of fabric or vinyl to create specialty padded designs like pleated upholstery.

Other Foam

Working with Upholstery Foam

Packaging

Foam will be shipped to you rolled up tightly. After you unroll the foam, please allow up to 24 hours for the foam to expand to its correct dimensions.

Once the foam is exposed to air, it will start to yellow, so don’t be concerned when this happens.

Cutting Foam

Foam can easily be cut with a serrated knife, or even an electric knife. See our video on how to cut foam.

Foam Spray Adhesive

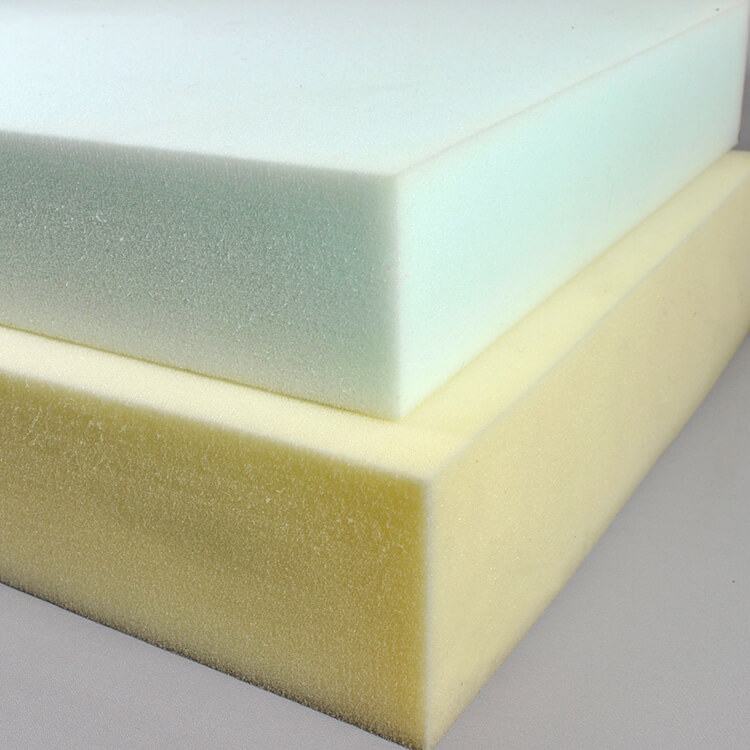

For more complex shapes and layering, you can use spray adhesive to bond the foam together. You can also spray adhesive to attach padding or upholstery batting to the foam to make cushions and headboards softer and more rounded.

Tutorials Using Foam

See the following tutorials that use foam for more tips on cutting foam and using for upholstery.